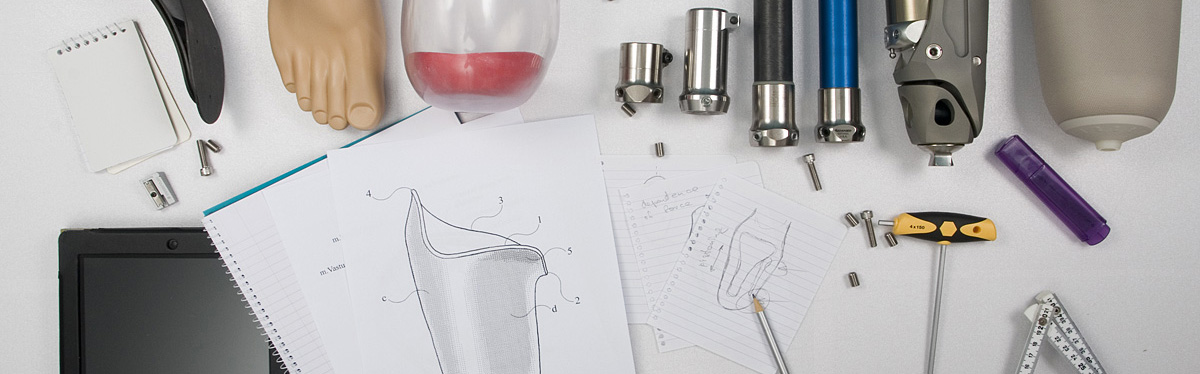

As with other prosthetic components like prosthetic knee joints, the design of a prosthetic foot aims at imitating the functions of the anatomical human foot. Unlike the knee which is a comparatively simple hinge joint, the foot is a complex structure comprised of 26 small bones held together by an intricate mesh of ligaments and moved and supported by over 20 different muscles that extend up into the lower leg. This system allows us to maintain our balance and walk over different terrain with minimal conscious effort which is a very difficult task to replicate in a mechanical device.

Before we can discuss the differences between prosthetic feet, we need to understand how the real human foot works and to do that we will look at the key functions our feet provide:

• Energy storage

• Surface adaptation

• Shock absorption

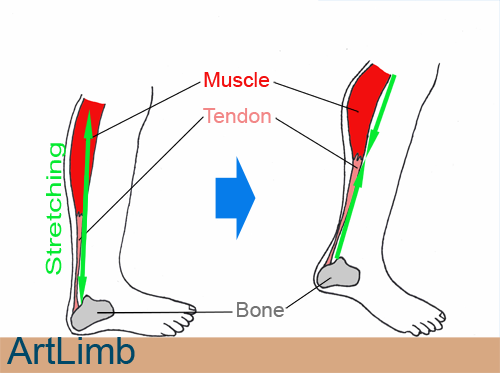

To walk, our body does not require the muscles to work at their full capacity. With each step the large muscles and tendons of the calf are passively stretched like an archer’s bow being drawn. Part of the required energy for the next movement is stored and released allowing us to walk greater distances before tiring.

The picture above demonstrates how muscles and tendons are passively stretching and storing energy during walk.

Our world is not perfectly flat. In our day to day lives we encounter slopes, uneven ground and small obstacles that we need to get over. The complex anatomical structure of the foot with its numerous joints gives us ability to walk safely over these surfaces by providing a reliable and mobile platform that can accommodate instantly without affecting our balance.

The photo above demonstrates how the foot adapts to the ground. It is visible that the body maintains its vertical position all times.

Our body is very sensitive to impacts with the brain being particularly susceptible. To protect us from the jarring forces that arise from walking we have evolved with several mechanisms to reduce damage by dampening these impacts. One of these mechanisms is the arch of the foot which works like the leaf spring suspension in motor vehicles. In addition to this the movement of the ankle joint further assists in absorbing the shock that occurs when the foot first contacts the ground.

The picture above shows an arch of the foot.

Currently, there are numerous models of the feet available in prosthetic industry which all attempt to replicate the three above functions to differing extents.

As always, in this article, we will try to explain the different styles and designs of feet rather than talk about specific models or manufacturers. To try and highlight the constant evolution of prosthetic design we will start with the simpler (and, in general, historically older) feet moving to the modern and more sophisticated designs. It is important to remember that generally speaking, the more complex the design, the more maintenance is required and the heavier the component will be.

S.A.C.H Foot

This abbreviation means “Solid-Ankle Cushion-Heel” and the design was first introduced in the prosthetic industry back in the 1950’s. Despite being an old design, the SACH foot is still used throughout the world due to its simple construction, relatively low weight and cheap manufacturing costs.

As the name suggests, this foot has soft heel that absorbs the impact that occurs when the foot first hits the ground (in prosthetics it is called “initial contact”, or “heel strike”). The internal solid counter or body of the foot is made from a rocker shaped block that allows the user to “roll” over the foot onto the toes. This design does not store energy and is very limited at adapting to different surfaces.

The photo above demonstrates a heel of the SACH foot deformation during the initial contact. It is visible that a soft heel works as a soft pad absorbing the impact.

Dynamic foot

Currently, this name has a more historical implementation rather than it defining how the foot works. This design can be considered as a development of the SACH foot that provides a smother rollover by means of flexibility in the forefoot.

Foot with monoaxial mechanical ankle.

This foot has an artificial single axis joint that replicates the ability of the ankle to move in the sagittal plane (flexion). The stability of this joint is usually tuned by a Prosthetist using interchangeable elastic bumpers. This style of foot can provide similar benefits to the SACH foot in terms of impact absorption with further benefits to accommodating to slopes but at the cost of greater energy loss making distance walking more physically taxing.

The photo above demonstrates a foot with monoaxial mechanical ankle.

Foot with multi-axial mechanical ankle.

After the single axis was designed, the logical direction was to design a foot that could replicate the inversion and eversion movement of the anatomical foot. By allowing this additional movement to the sides as well as flexion, the multi-axial foot can accommodate to uneven surfaces resulting in a more comfortable walk. Similarly to the single axial foot, this design is usually supplied with a set of elastic interchangeable bumpers to adjust ankle flexibility.

The photo above demonstrates a foot with the multi-axial mechanical ankle.

Energy storing foot.

Towards the end of the 20th century, there were developments of modern composite materials in other industries that started to be adopted in prosthetic design. These new materials allowed for much lighter feet to be built that were capable of storing energy. The most common composite materials used in prosthetic design are based on carbon fiber and fiberglasselastic technology.

The modern prosthetic industry has hundreds of different designs and combinations of composite fibers arranged in ways that try to provide the maximum amount of energy retention while providing different levels of surface adaption and impact absorption. The simplest models consist of a flat composite plate which plays the role of a simple spring working within one plane with limited energy storing effect.

The more sophisticated designs have the composites shaped into S-, O- or J- shapes to improve energy storage, heel strike dampening, smooth rollover, eversion/inversion and some vertical shock absorption.

The photo above shows a foot with plastic S-shape spring.

The photo above shows a carbon fiber energy storing foot with an O-shaped spring that provides a smoother rollover.

The photo above shows a carbon fiber foot with a split design to provide a comfortable walk on uneven surface. Working of the split toe is shown on the right. It is visible that, depending on the angle between the foot and the ground, left and right springs bend differently imitating ankle inversion and eversion.

Foot with pneumatics.

This design usually combines one or several composite springs coupled with a pneumatic cylinder system. The composite springs provide the energy storing while the pneumatic system can provide an adjustable and more controllable shock absorption at initial contact.

Foot with hydraulic ankle.

This design usually combines a relatively short composite spring with a hydraulic cylinder. In contrast to pneumatics, a hydraulic system is usually used across a single axis ankle joint to provide a very slow adjustable movement in the sagittal plane. This slow movement allow ankle to keep some certain angle of flexion and helps walk up and down slopes.

Electronic (CPU) foot.

This design usually combines a multi-axial composite system combined with a microprocessor controlled hydraulic system. These styles of feet provide some additional yet important functions such as faster adaptation to slopes and uneven surfaces.

The photo above demonstrates a carbon fiber foot with electronic ankle. It is visible that the foot has a relatively long composite spring.

The photo above demonstrates another approach – multiaxial foot with hydraulic system controlled by CPU.

Specialty Feet

Running foot

These feet were designed exclusively for running and consist of the very long single composite spring which are often referred to as a “blade”. These designs sacrifice the natural appearance of a foot for a very strong energy return effect. The specific shape and stiffness of these running blades are highly depending on running style and can be further customized with heel springs.

The photo above shows an example of the running foot.

Foot for recreational sports activity.

This design can be considered as a compromise between a highly specialized running foot and a foot for everyday use.

The photo above shows an example of the foot for recreational sport activity. It is visible that the foot has a quite long blade with heel and cosmetic cover, so it is suitable for walk, jogging, volleyball playing etc.

Conclusion

The last 100 years have seen massive developments in the field of prosthetic feet from simple peg designs to microprocessor technologies. However, as is common, there are a lot of different designs and models of feet in current use due to different factors, such as level of activity, lifestyle and bodyweight of the wearer, as well as an environment where their prosthesis is going to be used and the specific goals they want to achieve using their prosthesis.

For this reason, it is important to understand which of the three main functions are most important and decide on a foot in accordance to the indications, contraindications and the individual user’s actual prosthetic needs.

Important notice about illustrated materials contained in this article.

ArtLimb is a non-profit web recourse and is committed to the principle of freely accessible information. However, in this article we are publishing some visual materials through the courtesy of the copyright holders. Before reprinting and commercial use, please ensure you are not infringing existing copyrights.