The socket is the part of the prosthetic limb that is in contact with your body. This part of the leg is probably the most important, because its where your body weight is transferred to the prosthetic limb. The reason we spend so much time on this part is to make sure the weight is distributed safely and comfortably to protect your stump and joints.

Currently there are two opposite points of view when it comes to designing prosthetic socket.

The conventional style loads specific areas of the stump that were thought to be particularly pressure tolerant. Over time the specific pressure applied to the stump from this design can lead to issues with restricted blood flow and soft tissue atrophy (long term loss of mass and strength).

The second idea, known as hydrostatic, is to spread the load equally over the entire surface of the stump as if suspended in liquid. According to our point of view, this method is particularly difficult to put in to practice because anatomical structures in the stump have different densities, therefore have different tolerance to pressure and in general do not comply with the definition of hydrostatic system.

From our experience, we find the most comfortable and functional design for sockets uses a combination of both principles. In our sockets we spread the load through the entire surface of the stump with the level of the load depending on how tolerant places of the stump are to pressure. For example structures like sensitive bony areas, nerve clusters or scarred skin will be loaded less than non affected areas of the stump.

The main characteristics of the sockets we design are that they must be light weight, reliable for the user’s activity level as well as being comfortable to wear.

To provide all of these characteristics, we use a combination of several different materials such as structure forming carbon fibre, flexible plastics and compressible composite foams.

To further implement our idea of spreading the load appropriately over the whole stump, the majority of our sockets incorporate prosthetic liners. These liners range from relatively firm silicon to much softer gels. The majority of these liners can also be used with flexible soft inner sockets to improve cushioning when needed.

Below Knee

Photo below demonstrates the still common transtibial (below knee) socket design with a very narrow pressure area between the back of the knee and just under the knee cap. This provides a firm lock to hold the stump off the bottom of the socket by overloading the soft tissues in these areas. The area in the back of the knee contains several major blood vessels and nerve pathways that we do not want to overload.

Photo below demonstrates our approach that aims at spreading the load over a larger area while still building relief for sensitive structures. This socket does not apply point pressures on any of the major blood vessels or nerve pathways. By having total contact with the stump, this socket provides better control of the prosthetic leg.

Above Knee

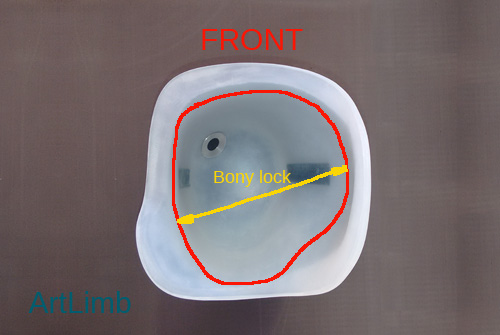

Photo below demonstrates the still common socket design with a very narrow pressure area between the front and back walls. This provides a firm lock to hold the stump off the bottom of the socket by overloading the soft tissues in these areas (upper part of the front wall). This area contains several major blood vessels and nerve pathways that we do not want to overload. These sockets are difficult to control because there is no correct position of th femur (large bone in the leg).

Photo below demonstrates a variation of the Ischial containment sockets that do not have an overloaded front area. This design prevents the stump falling into the socket by means of a “bony lock” between the pelvis and the femur. This socket works very well for certain stump types but is not ideal for everyone.

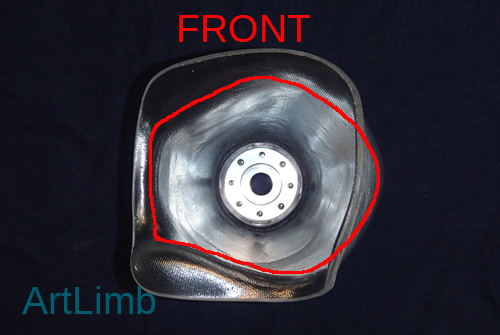

Photo below demonstrates a pentagonal socket design where load is spread through five walls that are shaped to the underlying structures of the limb. This socket does not have any point pressures, provides adequate control and is able to be fitted to a wide range of stump shapes and sizes.

Through Knee

Photo below demonstrates the still common through knee socket with soft foam inner and rigid outer construction. Fixation of this socket is provided by compressing the soft tissues over the condoyles (bony prominences above the knee). Constant pressure in this area can lead to uncomfortable feeling and even gradual weakening of the soft tissues.

Photo below demonstrates a combination of rigid outer socket, a flexible inner socket and a prosthetic liner with a valve. This design provides reliable fixation while unloading the bony structures over the knee

Partial Foot

Photo below demonstrates a very short prosthesis which spreads the forces through a very short section of the shin. By not including enough length inside the socket, this design does not provide enough control of the prosthetic foot and concentrates the pressure on a small area of the skin.

Photo below demonstrates an extended prosthesis that spreads the forces over a longer lever arm (distance) and reduces the pressure on the skin. This design complies with the same principles of spreading the load relatively evenly through a large surface area allowing for better control of the prosthetic foot.